High Brightness X ray Screens

High light emitting and brightness X ray screens are available for radiography upto 450 keV. We can provide these screens in gadox as well as phosphour.

A variety of backing and mounting options are available for the screens.

We have the knowledge and expertise based on years of experience to partner you in the development of custom products for X-ray imaging in NDT & other applications. Resolution, sensitivity, speed & colour of response are a few of the parameters that can be influenced in the production of a customised product that more closely relates to your customers’ need.

Products & Properties

Formulations. Scintacor offers three types of Gadox scintillator screens (sometimes referred to as luminescent screens or intensifying screens): Luminex (made of terbium-doped gadolinium oxysulphide (Gadox:Tb). This phosphor, also known as P43 and Rapidex (made of praseodymium-doped gadolinium oxysulphide (Gadox:Pr) for hard X-ray applications (50-300 KeV) and MeVex (is a very high coating weight screen made of terbium-doped gadolinium oxysulphide (Gadox:Tb) for use at high-energy energy levels (>450 KeV – 25 MeV). The properties of these screens are listed in Table 1.

Size & geometry. Unlike other commercially available products, Scintacor X-ray screens can be ordered in single units and custom-cut to any shape and size, to match the specific requirements of each application. Large sheets are available with linear dimensions up to 1,000×1,750mm. On request, the screens can also be supplied in precision-cut strips as thin as 3-4mm for coupling to linear diode arrays. They can be mounted on a variety of substrates for easier handling and deployment.

Table 1 X-ray Scintillator Screens: Basic Performance

| Luminex | Light Output (1) | MTF % @ 2lp/mm (2) | MTF % @ 5lp/mm (2) | Attenuation % (2) | Decay to 10% μs | Afterglow @ 20ms % |

| Ultrabright | 205% | 18 | 4 | 92 | 1,500 | <0.1% |

| Bright | 175% | 21 | 7 | 92 | 1,500 | <0.1% |

| Medium | 170% | 23 | 5 | 91 | 1,500 | <0.1% |

| Fine | 129% | 42 | 15 | 86 | 1,500 | <0.1% |

| UltraFine | 70% | 65 | 29 | 83 | 1,500 | <0.1% |

| UltraFine+ | 50% | 76 | 45 | 76 | 1,500 | <0.1% |

| Rapidex | Light Output (1) | MTF % @ 2lp/mm (2) | MTF % @ 5lp/mm (2) | Attenuation % (2) | Decay to 10% μs | Afterglow @ 20ms % |

| Bright | 92% | 16 | 4 | 97 | 7 | <0.1% |

| Medium | 91% | 19 | 5 | 94 | 7 | <0.1% |

| Fine | 81% | 32 | 9 | 89 | 7 | <0.1% |

| MeVex | Light Output (1) | MTF % @ 1lp/mm (2) | MTF % @ 2lp/mm (2) | Attenuation % (2) | Decay to 10% μs | Afterglow @ 20ms % |

| Medium | 242% | 16 | <10 | 98 | 1,500 | <0.1% |

(1)Relative to Lanex Regular benchmark screen. X-ray source: 150kV unfiltered

(2)X-ray source 70kV

Replacement screens

The Luminex screens can be used as replacement for x-ray scintillator screens by other manufacturers. Table 2 below provides the approximate equivalence among Scintacor designations and those of other manufacturers. This table does not imply the exact equivalence of the various screens and we invite you to contact Scintacor personnel for further guidance.

Table 2 – X-ray Scintillator Screens: Comparison table (*)

| Scintacor | Mitsubishi | Carestream | Agfa |

| Ultrabright | PI200 | – | – |

| Bright | DRZ-High | Lanex Fast | Ortho Fast |

| Medium | DRZ-Plus | Lanex Regular | Ortho Regular |

| Fine | DRZ-Std | Lanex Medium | Ortho Medium |

| UltraFine | DRZ-Fine | Lanex Fine | Ortho Fine |

| UltraFine+ | DRZ-HR | Lanex Min-R | – |

(*) Disclaimer. Headings and keywords in the table above are descriptive of the products offered by Scintacor to show which of Scintacor’s products is best suited as replacement of a similar product made by another company. The trademarks P100/DRZ, Lanex/MinR and Ortho are the property of Mitsubishi Chemical Corporation, Carestream Health and Agfa HealthCare respectively.

X-ray Screen Applications

Dual energy detectors for baggage / end-of-line inspection

In dual energy imaging systems, two radiation sensitive detectors are superimposed one behind the other. The front detector records and absorbs the low-energy photons, while transmitting the higher energy photons for detection to the thicker back detector. The two data sets are acquired simultaneously and provide information to image the density as in a normal radiograph and the atomic number of the target object [1] which is a considerable advantage. Luminex and Rapidex screens, which can be precision-cut in strips according to the customers requirements, are the ideal scintillator choice for low energy detectors, due to their low costs, high uniformity between batches and possibility to match the screen resolution to the pixel pitch of the detector. Luminex are generally preferred for low frame rate applications, when light output and resolution are the main priorities. Rapidex used in high frame rate application for end-of-line inspection up to speeds of a few meters per second.

Radiographic inspection of large-scale objects

X-ray and gamma radiography of large objects such as sculptures, large engine blocks or rocket nozzles is straight forward with Luminex screens, which can be provided with linear dimensions up to 1,000×1,750mm. They can be mounted on aluminium or other rigid substrates for ease of handling and deployment.

X-ray cabinets for postal screening

Cabinet X-ray scanners offer a compact and cost effective first line of defence against mail-delivered threats without the operating costs and space requirements of a conveyor based X-ray system. The Luminex Ultrabright, Bright and Medium screens are optimized for maximizing brightness in light starved condition such as the lens coupled systems, where resolution is less critical.

Ultra-high speed imaging

Due to their fast decay time, Rapidex screens can be coupled to ultra-fast cameras to image events which cannot be captured using normal X-ray imaging techniques. Applications include flash-radiography for industrial, scientific and defence research applications.

Dual energy computed tomography (DECT)

Dual energy computed tomography (DECT), also known as spectral imaging, is a new technology which combines the benefits of traditional CT scanners, with those of dual energy X-ray systems. CT scanners have the ability to take multiple cross sectional images of solid objects and to reconstruct a 3D model. Traditional dual-energy systems can provide information about the density, as well as the atomic number of the target object. In dual energy computed tomography (DECT), these two capabilities are combined to generate a 3D model with additional information on material composition. The Luminex Ultrafine and Ultrafine+ are a perfect match for DECT applications, where image sharpness is paramount.

Electron beam detection in SEM/TEM

For electron beam detection using scintillator viewing screens visit our product page Viewing screens for electron beam. For electron microscopy using Luminex Ultrafine+ please contact the Scintacor product’s team to discuss your requirements.

Backscatter detectors

Due to their high sensitivity and fast decay time, Rapidex screens have been successfully used in back-scatter imaging systems, where the photons which are Compton scattered from the target object, rather than those attenuated by it, are used to generate the image [2]. In recent years backscatter detectors have found growing use in security applications, as this technique allows detection of organic materials, such as explosives or human tissue. It also enables the positioning of the detector side by side compactly with the x-ray source with clear operational advantages for the scanning of vehicles and other moving targets. In this application high sensitivity is essential, as backscatter detectors operate at relatively low energies, when the Compton effect is the predominant method of interaction between photons and free electrons and the probability of scattering back an incident photon towards the origin is higher [3]. In addition, the energy of a scattered photon is always lower than the energy of the incident photon, hence the need of phosphor screens with high sensitivity such as the Rapidex range. Fast decay time is also important, as backscatter system often operate according to a flying spot technique, which was developed by American Science & Engineering (AS&E) in the 1970s [4].

Other Applications

Scintacor’s X-ray scintillator screens can be successfully used in a wide range of applications including, but not limited to security X-ray, end of line inspection X-ray, X-ray diffraction (XRD), X-ray powder diffraction, general X-Ray radiography, non-destructive testing (NDT), end-of-line inspection.

High resolution X-ray detectors

For customers interested in an integrated solution, Photonic Science and Engineering Ltd. can provide high resolution X-ray detectors where Scintacor scintillation screens are coupled to the latest CCD, EMCCD, sCMOS sensors.

Why Scintacor?

Levy and West, the founders of the renowned laboratories which later became Applied Scintillation Technologies and then Scintacor, were among the pioneers who explored the use of zinc sulphide phosphors for fluoroscopic X-ray imaging [5] [6]. Since then, many additional phosphor systems have been developed and today we find gadolinium oxysulphide (Gd2O2S or simply Gadox / GOS) phosphor is one of the most widely adopted for several reasons. The material morphology is well known and well controlled; the luminescent efficiency is relatively high (approximately 15%) and the emitted light matches well with the spectral response of silicon light detection devices such as charge-coupled detectors (CCD) and complementary metal oxide semiconductors (CMOS) [5].

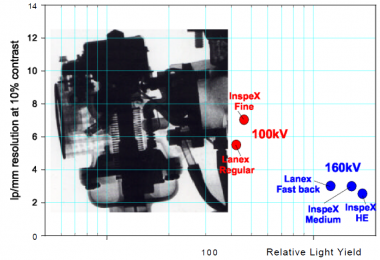

Gadox scintillator screens were originally developed and commercialized by companies which supplied photographic film and were often described as ‘fine’, ‘regular’ or ‘fast’ depending upon the film speed and spatial resolution of the film with which they were paired [5]. These screens are still widely available up to a maximum size of 14’’x 17’’ but they do not always provide the optimal solution for digital X-ray imaging [5]. Conversely, Scintacor phosphor screens have been specifically designed around digital X-ray imaging systems to provide differentiated performance over standard scintillator screens, in both lens-coupled systems, and direct-coupling to solid-state light detectors, such as CMOS and CCD.

Luminex screens are made of terbium-doped gadolinium oxysulphide (Gadox:Tb). This phosphor, also known as P43 [7], is one of the most efficient scintillators available in terms of light output per incident X-ray energy, due to its high atomic number and density, which make it an effective absorber of X-rays. For a given thickness, Gadox is a more efficient scintillator than Caesium Iodide (CsI), except in a window between 35 and 50 KeV, which corresponds to the interspace between the k-edges of caesium and gadolinium respectively. In addition, the emitted light (545 nm) matches the spectral response of the most common silicon photosensitive devices and allows these to operate at high quantum efficiency (QE). The Luminex screens are available in six designations, which offer different trade-offs between resolution and light output. Fine, Ultrafine and Ultrafine+ are thin screens designed for high-resolution applications such as digital radiography and are suitable for direct-coupling with large area CMOS and CCD detectors. Ultrabright, Bright and Medium are thicker screens ideal for lens coupled systems, which are generally light-starved but have lower resolution requirements than direct-coupling systems [5]. Typical applications for these thicker screens are cabinet X-ray systems for postal screening or industrial radiography of large-scale objects, such as rocket nozzles or engine blocks.

Rapidex screens are available in three designations and are made of praseodymium-doped gadolinium oxysulphide (Gadox:Pr), a phosphor optimised for high frame rate applications, where minimal afterglow and resistance to latent image burn-in are required. These applications include flying spot backscatter detectors; linear scanners for food and end-of-line inspection and area photosensitive devices for ultra-high speed imaging. As shown in Table 1, the decay time to 10% for the Rapidex screens is some 200 times faster than that of the corresponding Luminex item. However, Gadox:Pr is less efficient so that the light output of the Rapidex Medium is approximately half of that of a Luminex Medium, despite the two screens having comparable thicknesses and resolution properties. In addition, the emission of Gadox:Pr is slightly shifted to green, with a peak at 513 nm and this is likely to lead to marginally lower detector quantum efficiency than that achievable with a Luminex screen.

MeVex Medium is a very high coating weight screen made of terbium-doped gadolinium oxysulphide (Gadox:Tb), whose formulation and phosphor particle size distribution have been optimized for high-energy applications (>450 KeV – 25 MeV,) such as patient alignment systems in radiotherapy and gamma radiography in homeland security or scientific research.

Due to their insensitivity to moisture, radiation hardness, and relatively low cost, Scintacor scintillator screens are the ideal choice for X-ray imaging in many different industrial, security and research applications.

Digital X-ray Imaging

General Considerations

Performance of a scintillator screen is a trade-off between light output and resolution, which are controlled through three parameters. These are the coating thickness, the size of the phosphor particles and the packing density of the coating [8].

Increased thickness of the phosphor coating provides, in general, a higher conversion efficiency for the impinging X-rays into visible photons, which translates into a higher sensitivity and light output. There are nonetheless two caveats. Firstly, the resolution of the scintillator measured in line pairs per mm (lp/mm) will decrease with increased phosphor thickness, as the light is widely scattered within the phosphor layer. Secondly, the incremental gains of light output obtained for higher coating thicknesses will reduce until they disappear altogether, due to the self-absorption of the visible photons within the phosphor layers. The interested reader can refer to the work of Busselt and Raue, who propose a linear correlation between geometric thickness of the phosphor layer and the width of the light spread function [9].

Smaller phosphor particles result, in general, in a higher resolution but in a screen with lower light output, as the light generated inside the phosphor particles can escape in any directions and at an arbitrary point of its surface. On this basis, even for a single layer of phosphor particles, the smallest light emission spot approximately coincides with the phosphor particle size [10].

Finally, as a general trend, screens with a high packing density of particles have a better resolution but decreased brightness [11].

All this taken into account it should be remembered that the maximum brightness of the phosphor screen is ultimately limited by the quantum efficiency of the phosphor used. This is the reason why Scintacor scintillator screens are manufactured from highly controlled, premium-grade phosphors.

Terms

Digital radiography (DR) is a one-step process where the X-ray signal is converted into an electrical signal, either directly, as in amorphous selenium (a-Se) based systems, or indirectly, as in the systems using a scintillator layer in combination with a photodetector. Thallium doped micro-columnar Caesium Iodide (CsI:Tl) and Gadox screens are the most common scintillators used in digital radiography. Caesium Iodide is generally the preferred choice in medical and dental applications, where the benefits offered by this structured scintillator (higher resolution and higher sensitivity), translate into better image quality and lower X-ray doses to patient. Gadox screens still retain the lion’s share in industrial applications, such as non-destructive testing (NDT) and end of line inspection (EOL), where pressure on costs is higher, but resolution and dose-efficiency requirements are generally lower than those in the medical industry. Scintacor can provide to their customers both, CsI:Tl plates and Gadox screens whilst advising on the best scintillator characteristics for each specific application. Caesium Iodide (CsI:Tl) is treated more in detail in a separate product page of the website.

Computed radiography (CR) is a two-step process where phosphor plates made in photo-stimulable phosphors (PSP), such as europium-doped barium flurochloride (BaFCl:Eu), are used to store energy upon X-ray exposure. CR is often used as a means of retrofitting analog X-ray systems by replacing the traditional film cassette with a CR-specific cassette, which contains the PSP plate and is exposed to X-rays in the usual way. During the subsequent reading of the plate in a scanner, a focused laser beam triggers the release of the stored image data in the form of visible light. The emitted light is then detected and converted into a digital image with spatial information provided by the spot being excited by the laser. While Scintacor does not have standard CR offerings, the company has the expertise and equipment necessary to produce tailored photo-stimulable phosphor screens up to 1,000×1,750mm on demand.

Despite the significantly higher cost, DR systems have notably improved workflow vs. CR, as more images can be taken and processed in the same amount of time. Even more significant is that DR has at least twice the dose efficiency of CR or traditional film. This, in turn, results in lower doses to the patient and less exposure risk to the technicians.

Links

Contact

Geebee International

12 - A, Lane W - 16,

Sainik Farms,

New Delhi - 110062

+91 98107 54666, +91 11 4301 4983